Vertical Slotting Machine

Perfect for creating precise slots on metal surfaces, allowing adjustable depth and angle, meeting the needs of detailed manufacturing.

Product Advantages

WS11KY Series CNC full hydraulic variable roller spacing horizontal down-adjustment three-roller plate bending machine is the latest horizontal down-adjustment three-roller plate bending machine, which can complete the end pre-bending and rolling of sheet metal in one feeding.

High-Quality Work Rolls and Bearings

The work rolls are made of tempered roll steel, providing high strength and wear resistance. Each machine comes with a certificate including chemical composition, hardness testing, and ultrasonic inspection reports. The bearings use extra-wide self-aligning roller bearings, ensuring high load capacity and extended service life.

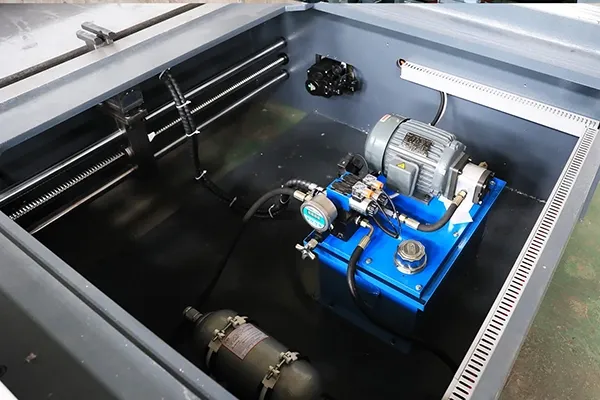

Advanced Hydraulic System

The hydraulic system is independent of the machine body for easier maintenance and is equipped with cooling and oil temperature heating devices to ensure stability and long-term reliability. The upper roll press is driven by a twin-cylinder system arranged in an up-and-down configuration for stable performance.

Flexible Roll Structure Design

The distance between the two lower rolls can be infinitely adjusted and configured in a “V” shape. Each lower roll can move independently or synchronously, enabling pre-bending and symmetrical rolling. In some models, the two lower rolls are fixed but can move horizontally together, with the upper roll passively rotating, driven by two independent motor reducers. This eliminates mechanical interference and vibration while being energy-efficient.

Full Three-Roll Drive

The upper and lower work rolls are independently powered by hydraulic motors and planetary gearboxes, delivering strong and efficient drive performance for precise and efficient processing.

Multi-Functional Control System

The control system is independently developed and leads the industry. It supports both manual and automatic (or micro-control) operations, with seamless switching between modes to meet diverse production needs. The system also offers intelligent adjustment, quickly correcting defects like misalignment or uneven ends during processing.

Dual Operation Systems

Equipped with both a remote controller and a mobile operating console, the systems are safety interlocked, ensuring only one system can be used at a time for secure and convenient operation.

High-Precision Design

Hydraulic cylinders drive the lower rolls vertically along guide rails, while the side rolls tilt along guide rails, providing precise control over the rolling process. The machine ensures minimal straight edges during pre-bending and delivers high accuracy for demanding applications.

Processing Flexibility and Quality Assurance

Any defects such as misalignment or uneven ends during the rolling process can be easily adjusted and corrected, ensuring consistent high-quality output with precise results.

Why choose us?

Long history

Tai’an Hualu Forging Industrial Control Technology Co., Ltd. has many years of industry experience and focuses on the research and development and manufacturing of plate rolling machines. We are well aware of market demand and technological trends. With a stable industry foundation, we provide customers with reliable and efficient equipment solutions to ensure that your production is always one step ahead.

Strong strength

The company covers a large area and has a modern production base and advanced production equipment. From research and development to manufacturing, every link reflects our strong comprehensive strength. Adequate resources and production capacity ensure high quality and fast delivery of products to meet your various customized needs.

Professional team

We have a large professional team covering technical support, installation and commissioning, and after-sales service. No matter where you are, we can provide timely response and efficient solutions to ensure smooth operation of equipment, reduce downtime, and let you use it with confidence.

Get Free Quote of Vertical Slotting Machine

Bed structure frame

- Adopting a fully welded structure design of high-strength steel, the bed frame has excellent rigidity and seismic resistance, and remains stable during heavy-load cutting.

- Its sturdy structure effectively extends the service life of the machine, ensures that the processing accuracy is not affected by external vibration, and is particularly suitable for high-precision and high-intensity continuous operations.

CNC system

- It uses well-known CNC systems such as Taiwan Easycat, which has a friendly operation interface and powerful functions. It supports custom programming of various process parameters, which is convenient and flexible to adjust the processing settings.

- The system has an intelligent error compensation function to ensure the accuracy and consistency of each slotting, greatly improve production efficiency, and is suitable for diversified and high-precision process requirements.

Hydraulic system

- The high-performance hydraulic system provides stable power output to ensure the smoothness and accuracy of slotting operations.

- The system is optimized to effectively reduce vibration and noise during operation, and supports high loads and long-term continuous work.

- The reliability of the hydraulic system not only ensures the safety of equipment operation, but also greatly reduces the maintenance frequency.

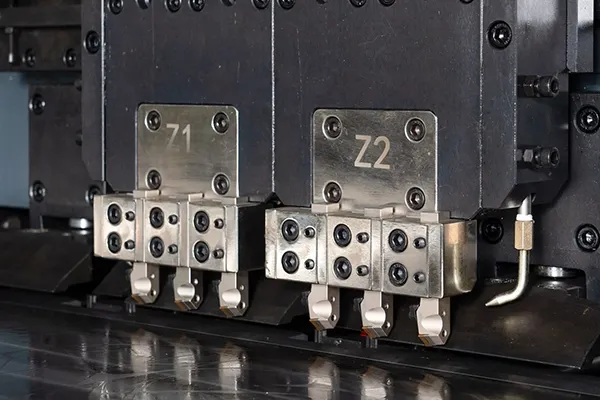

Alloy blade

- Use high-quality alloy blades with strong wear resistance, which are sharp and durable, and can easily cope with materials of different hardness.

- The excellent cutting performance of this blade reduces the frequency of thermal deformation and tool wear during processing, improves processing efficiency, and reduces replacement costs, bringing users a long-term use experience.