Swing Shearing Machine

Featuring a swinging blade design, it offers high cutting efficiency and low energy consumption, especially suited for thin sheets with low maintenance costs.

Product parameters

| TYPE | Cutting thickness(mm) | Cutting Width(mm) | Cutting angle(°) | Dimension(mm) | Material strength(KN/cm) | Stopper adjust range(mm) | Travel times(1/Min) | Power(kw) |

| 4*2500 | 4 | 2500 | 1°30′ | 3040x1550x1550 | ≤450 | 20~500 | 14 | 5.5 |

| 4*3200 | 4 | 3200 | 1°30′ | 3840x1550x1550 | ≤450 | 20~500 | 12 | 5.5 |

| 4*4000 | 4 | 4000 | 1°30′ | 4600x1700x1700 | ≤450 | 20~600 | 10 | 5.5 |

| 4*6000 | 4 | 6000 | 1°30′ | 6460x2100x2200 | ≤450 | 20~800 | 5 | 7.5 |

| 6*2500 | 6 | 2500 | 1°30′ | 3040x1710x1620 | ≤450 | 20~500 | 14 | 7.5 |

| 6*3200 | 6 | 3200 | 1°30′ | 3840x1710x1620 | ≤450 | 20~500 | 12 | 7.5 |

| 6*4000 | 6 | 4000 | 1°30′ | 4620x1850x1700 | ≤450 | 20~600 | 9 | 7.5 |

| 6*5000 | 6 | 5000 | 1°30′ | 3140x1710x1620 | ≤450 | 20~600 | 8 | 7.5 |

| 6*6000 | 6 | 6000 | 1°30′ | 6480x2100x2300 | ≤450 | 20~800 | 5 | 11 |

| 8*2500 | 8 | 2500 | 1°30′ | 3040x1700x1700 | ≤450 | 20~500 | 11 | 7.5 |

| 8*3200 | 8 | 3200 | 1°30′ | 3860x1700x1700 | ≤450 | 20~500 | 8 | 7.5 |

| 8*4000 | 8 | 4000 | 1°30′ | 4640x1700x1700 | ≤450 | 20~600 | 8 | 7.5 |

| 8*5000 | 8 | 5000 | 1°30′ | 5400x2400x2000 | ≤450 | 20~600 | 8 | 7.5 |

| 8*6000 | 8 | 6000 | 1°30′ | 6480x2100x2350 | ≤450 | 20~800 | 8 | 11 |

| 10*2500 | 10 | 2500 | 1°30′ | 3040x1800x1700 | ≤450 | 20~500 | 10 | 11 |

| 10*3200 | 10 | 3200 | 1°30′ | 3860x2000x1700 | ≤450 | 20~500 | 10 | 11 |

| 10*4000 | 10 | 4000 | 1°30′ | 4650x2100x2000 | ≤450 | 20~600 | 10 | 11 |

| 10*6000 | 10 | 6000 | 1°30′ | 6500x2100x2300 | ≤450 | 20~800 | 10 | 15 |

| 12*2500 | 12 | 2500 | 2° | 3140x2050x2000 | ≤450 | 20~600 | 12 | 18.5 |

| 12*3200 | 12 | 3200 | 2° | 3880x2150x2000 | ≤450 | 20~600 | 10 | 18.5 |

| 12*4000 | 12 | 4000 | 2° | 4650x2150x2000 | ≤450 | 20~600 | 10 | 18.5 |

| 12*5000 | 12 | 5000 | 2° | 6900x2600x2700 | ≤450 | 20~600 | 6 | 18.5 |

| 12*6000 | 12 | 6000 | 2° | 3140x2150x2000 | ≤450 | 20~1000 | 5 | 18.5 |

| 16*2500 | 16 | 2500 | 2°30′ | 3140x2150x2000 | ≤450 | 20~600 | 10 | 18.5 |

| 16*3200 | 16 | 3200 | 2°30′ | 3880x2150x2000 | ≤450 | 20~600 | 10 | 18.5 |

| 16*4000 | 16 | 4000 | 2°30′ | 4650x2150x2200 | ≤450 | 20~800 | 10 | 18.5 |

| 16*5000 | 16 | 5000 | 2° | 5900x2600x2700 | ≤450 | 20~1000 | 6 | 18.5 |

| 16*6000 | 16 | 6000 | 2° | 6900x2700x2700 | ≤450 | 20~1000 | 5 | 22 |

| 20*2500 | 20 | 2500 | 3° | 3440x2300x2500 | ≤450 | 20~800 | 8 | 22 |

| 20*3200 | 20 | 3200 | 3° | 4150x2350x2700 | ≤450 | 20~800 | 8 | 22 |

| 20*4000 | 20 | 4000 | 3° | 4850x2600x2400 | ≤450 | 20~1000 | 5 | 22 |

| 20*6000 | 20 | 6000 | 3° | 6700x3000x3000 | ≤450 | 20~1000 | 4 | 22 |

Products Categories

Get A Free Quote

Get Free Quote of Swing Shearing Machine

Structure

- Our shearing machine is built with a fully welded box frame, seamlessly integrated with the workbench. This solid structure provides excellent rigidity, effectively counteracting the torque loads generated during shearing.

- With a high-stiffness frame design, the machine maintains stability and precision, ensuring reliable performance under demanding conditions.

- The vertical linear movement of the upper blade relative to the lower blade reduces material distortion during cutting, preserving the straightness and accuracy of each sheared piece.

Main motor

- This product of ours is matched with well-known high-performance motors at home and abroad such as Siemens of Germany, Inovance of China, and Delta. We will match you with the most cost-effective motor based on your actual practical conditions.

- These motors offer exceptional durability and efficiency, significantly improving production continuity and stability and reducing downtime. Its strong torque output and precise speed control provide high performance guarantee for the equipment, making the shearing process smooth and smooth, ensuring that every operation can achieve the best results.

CNC system

- Our shears are equipped with a variety of advanced CNC systems, including the DELEM series (DAC-310 and DAC-360) high-end CNC system brands from the Netherlands, ESA from Italy, Cybelec classic CNC systems and economical and practical CNC systems from Switzerland ESTUN E21S.

- We provide a variety of systems to meet our customers’ needs in different production environments.

- Each system is carefully selected to ensure superior performance in a variety of applications. Whether your needs are basic shearing operations or complex automation, our combination of systems brings you optimal efficiency and precision.

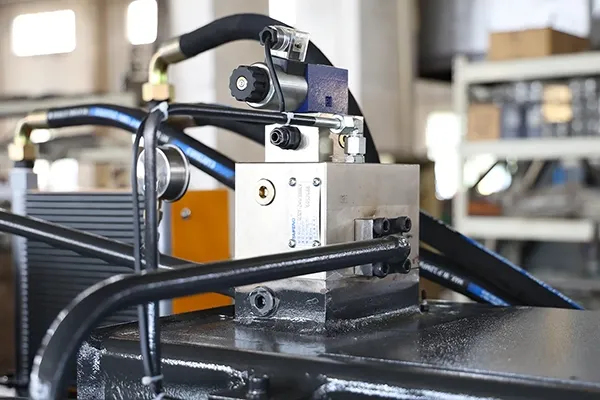

Hydraulic Valve

- Our machines use domestic high-performance hydraulic valve blocks such as Bosch Rexroth of Germany and Parker Hannifin of the United States, which are all well-known for optimal hydraulic control. Customers can choose cost-effective brands according to actual processing conditions.

- The integrated oil pressure overload protection system minimizes the risk of oil leakage and valve blockage, ensuring reliable and uninterrupted operation.

- In addition, real-time oil pressure monitoring improves stability by maintaining smooth oil circuit function, supporting consistent equipment performance.

Ball bearing table

- The ball bearing workbench is designed to reduce the friction resistance of the plate on the workbench, allowing the plate to slide and position more easily.

- With the ball bearing support, the workbench is more convenient to operate when loading and adjusting the plate, effectively improving the processing efficiency, while reducing the scratches or damage on the plate surface caused by friction.

- The application of the ball bearing workbench not only improves the accuracy of the shearing process, but also greatly improves the operating experience, making the overall operation of the shearing machine smoother and more fluent.

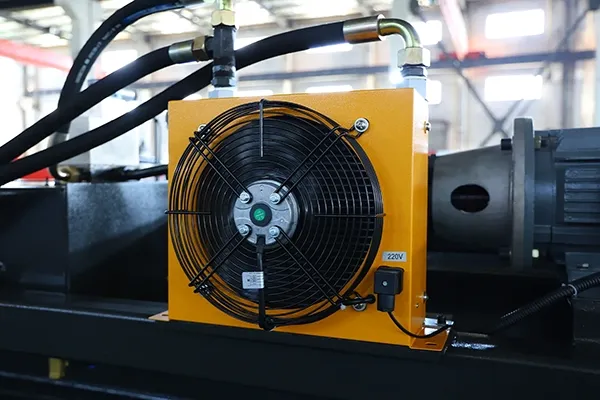

Hydraulic Oil Cooling Device

- This device is used in the hydraulic system of the shearing machine to ensure that the hydraulic oil maintains a suitable temperature during long-term operation.

- Through effective cooling, the hydraulic oil cooling device prevents the system from overheating, thereby maintaining the stability and performance of the hydraulic system.

- This device not only extends the service life of the hydraulic components, but also improves the operating efficiency and precision of the shearing machine, and is particularly suitable for high-intensity and continuous operation scenarios.

- The use of the hydraulic oil cooling device helps the equipment to maintain the best condition in harsh working environments and ensures the reliability and durability of the shearing machine.

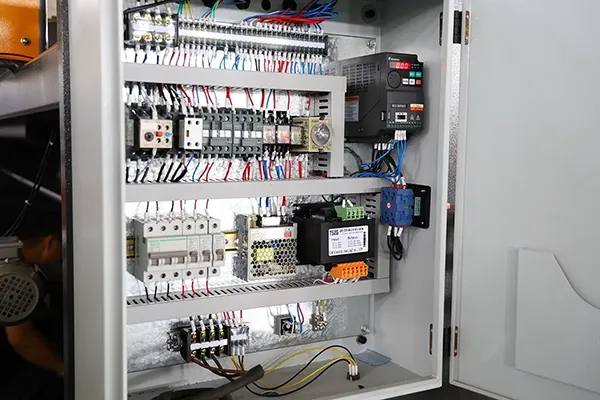

Electrical Components

- Our equipment uses high-quality electrical parts that perform reliably even with unstable power supply, and replacement parts are easily available worldwide.

- We use genuine Schneider components imported from France, known for their stability, durability, and long service life.

Related Products

Related News

[product_related_posts]