CNC Rolling machine series

Product Advantages

WS11KY Series CNC full hydraulic variable roller spacing horizontal down-adjustment three-roller plate bending machine is the latest horizontal down-adjustment three-roller plate bending machine, which can complete the end pre-bending and rolling of sheet metal in one feeding.

High-Quality Work Rolls and Bearings

The work rolls are made of tempered roll steel, providing high strength and wear resistance. Each machine comes with a certificate including chemical composition, hardness testing, and ultrasonic inspection reports. The bearings use extra-wide self-aligning roller bearings, ensuring high load capacity and extended service life.

Advanced Hydraulic System

The hydraulic system is independent of the machine body for easier maintenance and is equipped with cooling and oil temperature heating devices to ensure stability and long-term reliability. The upper roll press is driven by a twin-cylinder system arranged in an up-and-down configuration for stable performance.

Flexible Roll Structure Design

The distance between the two lower rolls can be infinitely adjusted and configured in a "V" shape. Each lower roll can move independently or synchronously, enabling pre-bending and symmetrical rolling. In some models, the two lower rolls are fixed but can move horizontally together, with the upper roll passively rotating, driven by two independent motor reducers. This eliminates mechanical interference and vibration while being energy-efficient.

Full Three-Roll Drive

The upper and lower work rolls are independently powered by hydraulic motors and planetary gearboxes, delivering strong and efficient drive performance for precise and efficient processing.

Multi-Functional Control System

The control system is independently developed and leads the industry. It supports both manual and automatic (or micro-control) operations, with seamless switching between modes to meet diverse production needs. The system also offers intelligent adjustment, quickly correcting defects like misalignment or uneven ends during processing.

Dual Operation Systems

Equipped with both a remote controller and a mobile operating console, the systems are safety interlocked, ensuring only one system can be used at a time for secure and convenient operation.

High-Precision Design

Hydraulic cylinders drive the lower rolls vertically along guide rails, while the side rolls tilt along guide rails, providing precise control over the rolling process. The machine ensures minimal straight edges during pre-bending and delivers high accuracy for demanding applications.

Processing Flexibility and Quality Assurance

Any defects such as misalignment or uneven ends during the rolling process can be easily adjusted and corrected, ensuring consistent high-quality output with precise results.

WS11K Series CNC Three-roll Plate Rolling Machine

WS11K CNC horizontal down-adjustable three-roller plate bending machine can realize the pre-bending and rolling of the end of the sheet metal at one time.

Thickness specifications 6mm-350mm, width specifications 1000mm-12000mm.

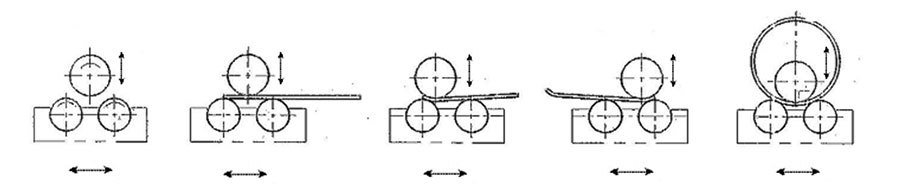

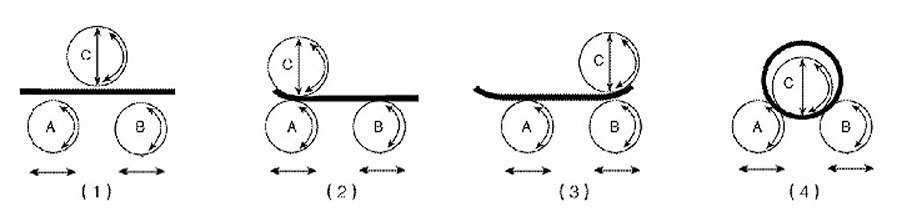

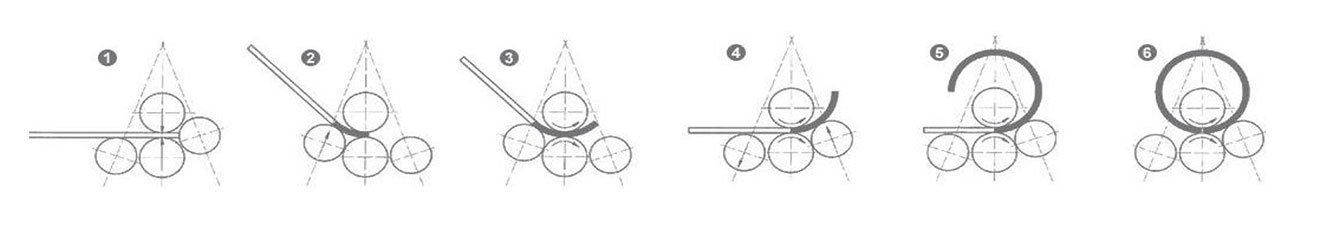

Three-roll Plate Rolling Machine Operating Principle

WS11KY Series CNC Three-roller plate bending machine

WB12KY numerical control full hydraulic four-roller plate bending machine can complete the end bending and rolling of sheet metal at one time.

Thickness specification 6mm-280mm, width specification 1000mm-9500mm

Three-roll Plate Rolling Machine Operating Principle

WB12KY Series Super Large Hydraulic CNC Four-roller Plate Bender

WB12KY numerical control full hydraulic four-roller plate bending machine can complete the end bending and rolling of sheet metal at one time.

Thickness specification 6mm-280mm, width specification 1000mm-9500mm

Three-roll Plate Rolling Machine Operating Principle

Production workshop

Our production workshop is equipped with many large-scale processing equipment and CNC processing centers, which are specially designed for the production of large-scale equipment and have high-efficiency and high-precision processing capabilities. Combined with an experienced technical team and strict quality control, we ensure that the product performance is superior and the production is reliable.