WE43Y Series Precision Sheet Leveler

WE43M(Y) six-fold precision leveling machine is designed for aluminum and aluminum alloy plates, copper and copper alloys, molybdenum plates, titanium plates, zinc, tantalum, niobium and other light alloys and rare and precious metal plates. It adopts a variety of anti-dust adhesion and anti-plate surface scratch technologies, with high leveling accuracy and good processing quality.

- The six-fold roller system structure has an intermediate roller between the work roller and the support roller, which can effectively isolate the marks produced by the four-fold support roller on the plate surface and improve the surface quality of the plate.

- With advanced group drive control technology, the working roller adapts to the running speed of the plate, avoids scratches on the plate surface, and effectively protects the quality of the plate surface.

- Multi-roller roller warehouse, roller unit according to the processing needs to replace, to meet a variety of materials or a variety of thickness of the plate precision processing.

- Quick roll change system configuration, quick roll change device can be up and down the roll box (roll system) quickly removed, convenient roll system replacement, high efficiency of roll change time. According to the need of use

- Configure multiple stations.

- The pneumatic purging device cleans the plate surface before straightening to prevent dust or foreign matter from being pressed in and damaging the plate surface.

- Non-destructive loading and unloading, the use of vacuum suction cups for loading and unloading, to avoid the plate scratch.

- On-line roller body cleaning, equipped with an independent on-line cleaning device, can realize fast on-line cleaning of work roller surface adhesion.

Product Advantages

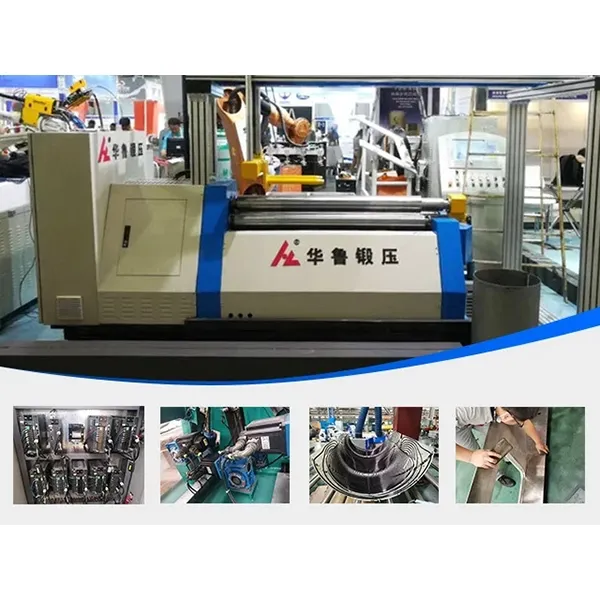

WS11KY Series CNC full hydraulic variable roller spacing horizontal down-adjustment three-roller plate bending machine is the latest horizontal down-adjustment three-roller plate bending machine, which can complete the end pre-bending and rolling of sheet metal in one feeding.

High Precision and Efficiency

The machine adopts single-piece beam adjustment technology, providing more pressing methods than conventional levelers. It supports parallel, inclined pressing, and V-shaped roller system arrangements, enabling bidirectional feeding. The independent pressing capability of the middle upper roller ensures thorough plate deformation, achieving superior leveling accuracy through the principle of over-correction.

Enhanced Safety and Ease of Operation

The enlarged feeding port solves the feeding challenges common in traditional upper roller systems with integral tilt adjustment. This design shortens auxiliary feeding time, enhances operational safety, and improves equipment reliability, making the entire process faster and more user-friendly.

Stable Leveling Performance

Using upper roller individual adjustment technology and variable roller distance design, the machine significantly improves the plate bending plastic deformation rate and minimizes leveling blind spots. This ensures a stable leveling process, effectively reduces internal residual stress, and enhances the stability of the plates during subsequent use.

Energy-Efficient Design

The machine allows the adjustment of the number of working rollers based on plate thickness, optimizing energy consumption. This feature not only reduces operating costs but also extends the machine’s service life, making it an environmentally friendly and cost-effective solution.

Advanced Automation

Equipped with an internationally advanced numerical control system, the machine automatically calculates pressure settings based on input parameters like plate thickness, width, and strength. It can also utilize a leveling expert database for parameter adjustments, ensuring quick and efficient workpiece leveling, significantly boosting production efficiency.

Smart Monitoring and Information Management

The optional production information system provides real-time monitoring of equipment operation and energy consumption data, including runtime, power, voltage, and energy usage. This enables efficient management and maintenance planning, improving operational reliability and reducing downtime.

Durability and Reliability

Key components are made of high-strength materials, processed with advanced machining and heat treatment techniques, offering excellent wear resistance. The machine is built to withstand long-term, high-intensity industrial use, ensuring stable and reliable performance.

Wide Range of Applications

With compatibility for various plate thicknesses and materials, the machine is versatile and suitable for diverse industries, including construction, aerospace, automotive, and heavy machinery. Its adaptability makes it a robust solution for precision leveling across multiple fields.