Press brake systems

Excellent CNC press brake systems to optimize your press brake

DELEM CNC Control System For Press Brakes

DELEM DA53T Touch Color CNC System

The DA-53T touch CNC control provides a modern compact and versatile solution for a wide range of press brake applications without compromising machine functionality.

- 10.1″ high resolution colour TFT

- “Hot-key” touch navigation

- Up to 4 axes (Y1,Y2 + 2 aux. axes)

- Tool / material / product library

- Advanced Y-axis control algorithms for closed-loop as well as open-loop valves.

- CNC Crowning control

- USB memory stick interfacing

- Profile-53TL offline software

DELEM DA58T Color 2D graphical CNC System

The DA-58T Touch CNC Control provides a modern, compact and versatile solution for powerful and economical press brake applications.

- 15″ high resolution color TFT

- 2D graphic touch screen programming

- Up to 4 axes (Y1, Y2 + 2 auxiliary axes)

- Bending sequence calculation

- Advanced Y-axis control algorithm for closed-loop and open-loop valves.

- CNC crown control

- USB, peripheral interface

- Profile-58TL offline software

DELEM DA66T Touch 2D Graphical Control

The DA-66T touch controller features an embedded real-time Windows operating system for maximum reliability, ensuring smooth startup even after a momentary shutdown.

- 17″ high-resolution color TFT

- 2D graphical touchscreen programming mode

- 3D visualization in simulation and production

- Complete Windows application suite

- Delem Modusys compatibility (module expandability and adaptability)

- USB, peripheral interfaces

- Profile-T2D offline software

- Sensor bending and correction interface

DELEM DA69T Touch 3D Graphical Control

The DELEM DA-69T offers 2D as well as 3D programming that includes automatic bend sequence calculation and collision detection. Full 3D machine set-up with multiple tool stations giving true feedback on the product feasibility and handling.

- 17″ high resolution colour TFT

- 2D and 3D graphical touch screen programming mode

- 3D visualisation in simulation and production

- Full Windows application suite

- Delem Modusys compatibility (module scalability and adaptivity)

- USB, peripheral interfacing

- Profile-T2D offline software

- Sensor bending & correction interface

Cybelec CNC Control

System

CYBELEC CybTouch 8 PS 2D graphic CNC System

CybTouch 8 PS is intended specifically for synchronized press-brakes.As part of the CybTouch range, it has an intuitive and vivid color touch screen and a high integration of functions.

- 7” color graphic CRT screen

- 2D graphic profile creation with manual sequencing

- Up to 4 axes (Y1,Y2 + 2-axes)

- Bend allowance calculation.

- Pressure – crowning calculation.

- CNC Crowning control

- Angle and back gauge correction.

- Delivered with PC1200 offline software.

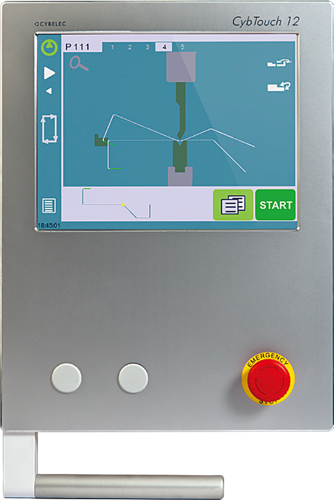

CYBELEC CybTouch 12 PS 2D graphic CNC System

As the entire CybTouch numerical control range, CybTouch 12 PS features an intuitive touch screen user interface, offering a high integration of functions.

- 12” color graphic with fully touch screen

- Touch 2D graphic part creation with manual sequencing

- Up to 4 axes (Y1,Y2 , X, R-axes)

- Bend allowance calculation.

- Pressure – crowning calculation.

- Modulable tools for each part or bend.

- Angle and back gauge correction.

- Delivered with PC-ModEva offline software.

CYBELEC CybTouch 15 PS 2D graphic CNC System

The CybTouch 15 PS is a 2D numerical control specifically dedicated for entry to mid-range CNC press-brakes. It comes in a compact housing, similarly to the well-known CybTouch range in the field, but offering a bigger touchscreen and a new horizontal design.

- 15” color graphic with fully touch screen

- Touch 2D graphical profile drawing and precise 2D program creation

- Up to 6 axes (Y1,Y2 , X, R ,Z1 , Z2-axes)

- Automatic bending sequence calculation

- Tandem management.

- Modulable tools for each part or bend.

- Angle and back gauge correction.

- VisiTouch 2D or VisiTouch MX offline software.

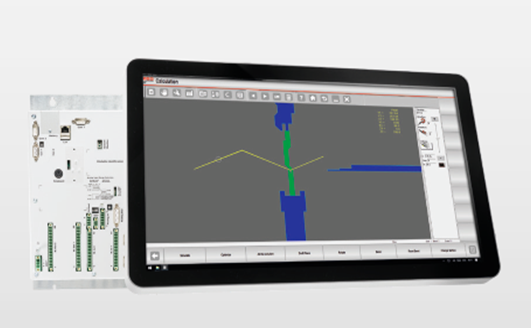

CYBELEC VisiTouch 19 2D and 3D graphical CNC System

The VisiTouch 19 and VisiTouch 19 MX is a 2D and 3D graphical numerical control for CNC press brakes. It aims at making the operator’s work easier, even for demanding programming and setting-up tasks.

- 19” touch screen modern streamlined glass surface

- Touch 2D graphical profile drawing and precise 2D program creation

- Easy operating thanks to the user-friendly HMI

- Automatic bending sequence calculation

- Internal backup and restore functions

- Modulable tools for each part or bend.

- Angle and back gauge correction.

- VisiTouch 2D or VisiTouch MX offline software.

ESA CNC Control System

ESA S630 2D Graphical CNC System

The most powerful in its class 10’ touch screen with powerful graphic All the performances of a high-level cnc in an economical and user-friendly controller.

- 10 inch LCD touch screen (Resistive)

- Touch 2D graphic part creation with manual sequence

- Stander to 4 axis(Y1Y2,X, R)

- Automatic bending force, crowning calculation.

- Modulable tools for each part or bend.

- Direct angle correction, also for the crowning.

- Proprotional and pressure valve Amplify intergrated.

- Free off-line PC simulation software.

- Tandem machine management(option)

- Modbus TCP interface for SCADA or MES(option)

ESA S640 2D Graphical CNC System

Top-level performances for machines up to six axes with automatic bending sequence calculations and Material Data Base for predictive compensation are available (as options) to reduce the wastage of material.

- 15 inch LCD touch screen (Resistive)

- Touch 2D graphic part creation with automatic sequence

- Stander to 4 axis, can up to 6 axis max.

- Automatic bending force, crowning calculation.

- Modulable tools for each part or bend.

- Direct angle correction, also for the crowning.

- Proprotional and pressure valve Amplify intergrated.

- Free off-line PC simulation software.

- Tandem machine management(option, can up to 4 machines)

- Modbus TCP interface for SCADA or MES(option)

ESA S650W 2D Graphical CNC System

No limit in both performances and flexibility. The powerful built-in Pc allows having on the machine a real 3D cad cam (metallix, radan, esa) Finger-tip work piece design. Direct import of tools shapes (.dxf files) and management of tool library. Tool and die holders management. Angle measurement and correction with all existing devices is available.

- 15 inch LCD touch screen (Resistive)

- DXF tools import(options)

- Touch 2D graphic part creation with automatic sequence

- Stander to 4 axis, can up to 32 axis max.

- Automatic bending force, crowning calculation.

- Modulable tools for each part or bend.

- Free off-line PC simulation software.

- Tandem machine management(option, can up to 4 machines)

- Modbus TCP interface for SCADA or MES(option)

- DataM or Iris-Plus angle messurement management(options).

- EsaBend-3D software(options)

- Metalix, Radan, AutoPol 3d viewer(options)

ESA S660W CNC System

A totally renewed interface, specifically designed for multi touch screen, is available as an alternative to the well-known Esa interface used on S650W.

Make the best of any 3D cad cam you would like to install in the CNC.

Finger-tip work piece design.

Direct import of tools shapes (.dxf files) and management of tool library.

Tool and die holders’ management.

- 19 inch LCD touch screen (Capacitive)

- DXF tools import(options)

- Touch 2D graphic part creation with automatic sequence

- Stander to 4 axis, can up to 156 axis max.

- Automatic bending force, crowning calculation.

- Modulable tools for each part or bend.

- Direct angle correction, also for the crowning.

- Free off-line PC simulation software.

- Tandem machine management(option, can up to 4 machines)

- Modbus TCP interface for SCADA or MES(option)

- DataM or Iris-Plus angle messurement management(options).

- EsaBend-3D software(options)

- Metalix, Radan, AutoPol 3d viewer(options)

ESA S675W CNC System

A totally renewed interface, specifically designed for multi touch screen, is available as an alternative to the well-known Esa interface used on S650W.

Make the best of any 3D cad cam you would like to install in the CNC.

Finger-tip work piece design.

Direct import of tools shapes (.dxf files) and management of tool library.

Tool and die holders’ management.

Angle measurement and correction with all existing devices is available.

- 21 inch LCD touch screen (Capacitive)

- DXF tools import(options)

- Touch 2D graphic part creation with automatic sequence

- Stander to 4 axis, can up to 156 axis max.

- Automatic bending force, crowning calculation.

- Modulable tools for each part or bend.

- Direct angle correction, also for the crowning.

- Free off-line PC simulation software.

- Bend database(options)

- Modbus TCP interface for SCADA or MES(option)

- DataM or Iris-Plus angle messurement management(options).

- EsaBend-3D software(options)

- Metalix, Radan, AutoPol 3d viewer(options)