Horizontal Grooving Machine

video

Watch the video to learn about the product.

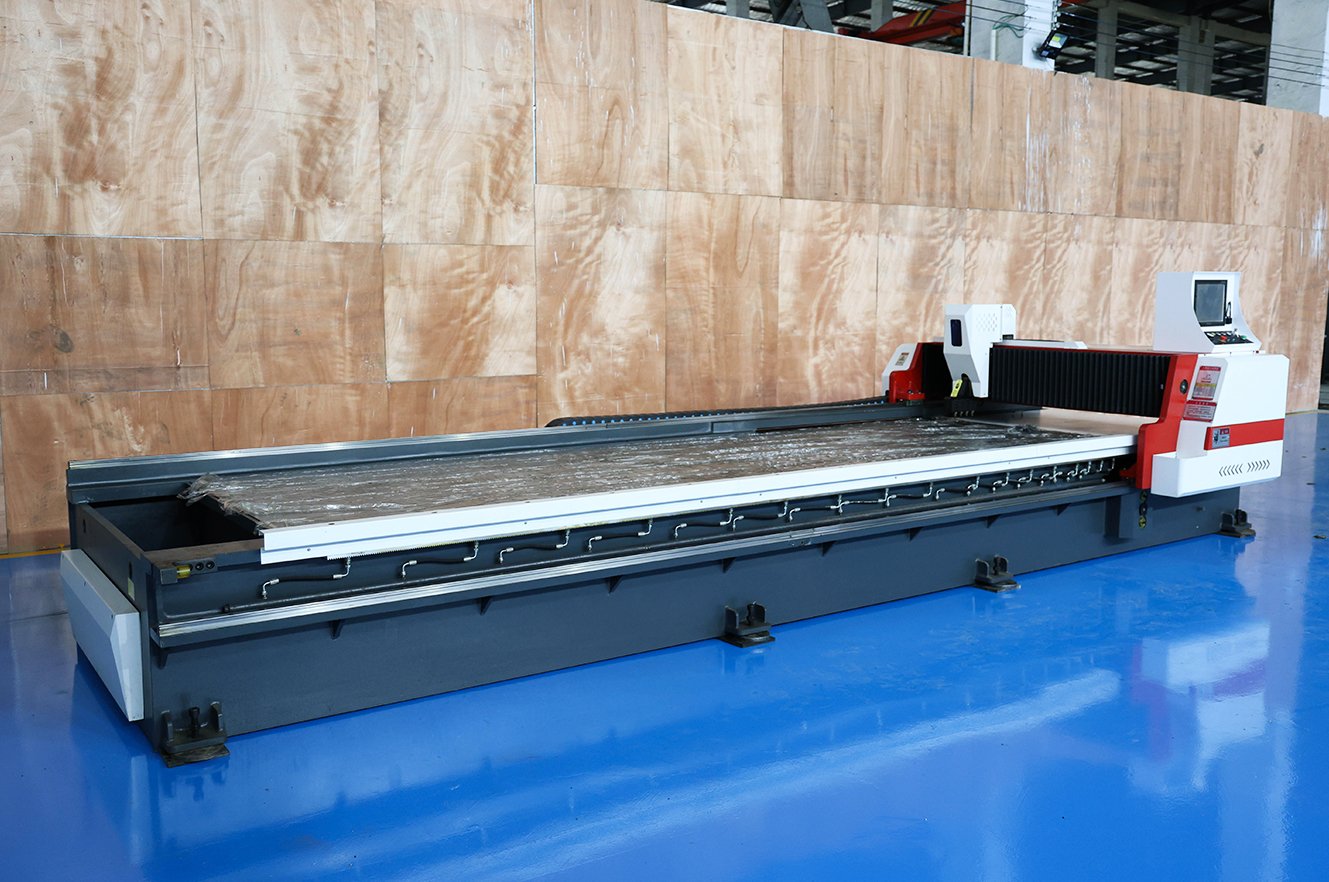

Bed structure frame

- Adopting a fully welded structure design of high-strength steel, the bed frame has excellent rigidity and seismic resistance, and remains stable during heavy-load cutting.

- Its sturdy structure effectively extends the service life of the machine, ensures that the processing accuracy is not affected by external vibration, and is particularly suitable for high-precision and high-intensity continuous operations.

CNC system

- Equipped with Taiwan Easycat CNC system, China, the operation interface is friendly and powerful, and supports custom programming of multiple process parameters, which is convenient for flexible adjustment of processing settings.

- The system has an intelligent error compensation function to ensure the accuracy and consistency of each slotting, greatly improves production efficiency, and is suitable for diversified and high-precision process requirements.

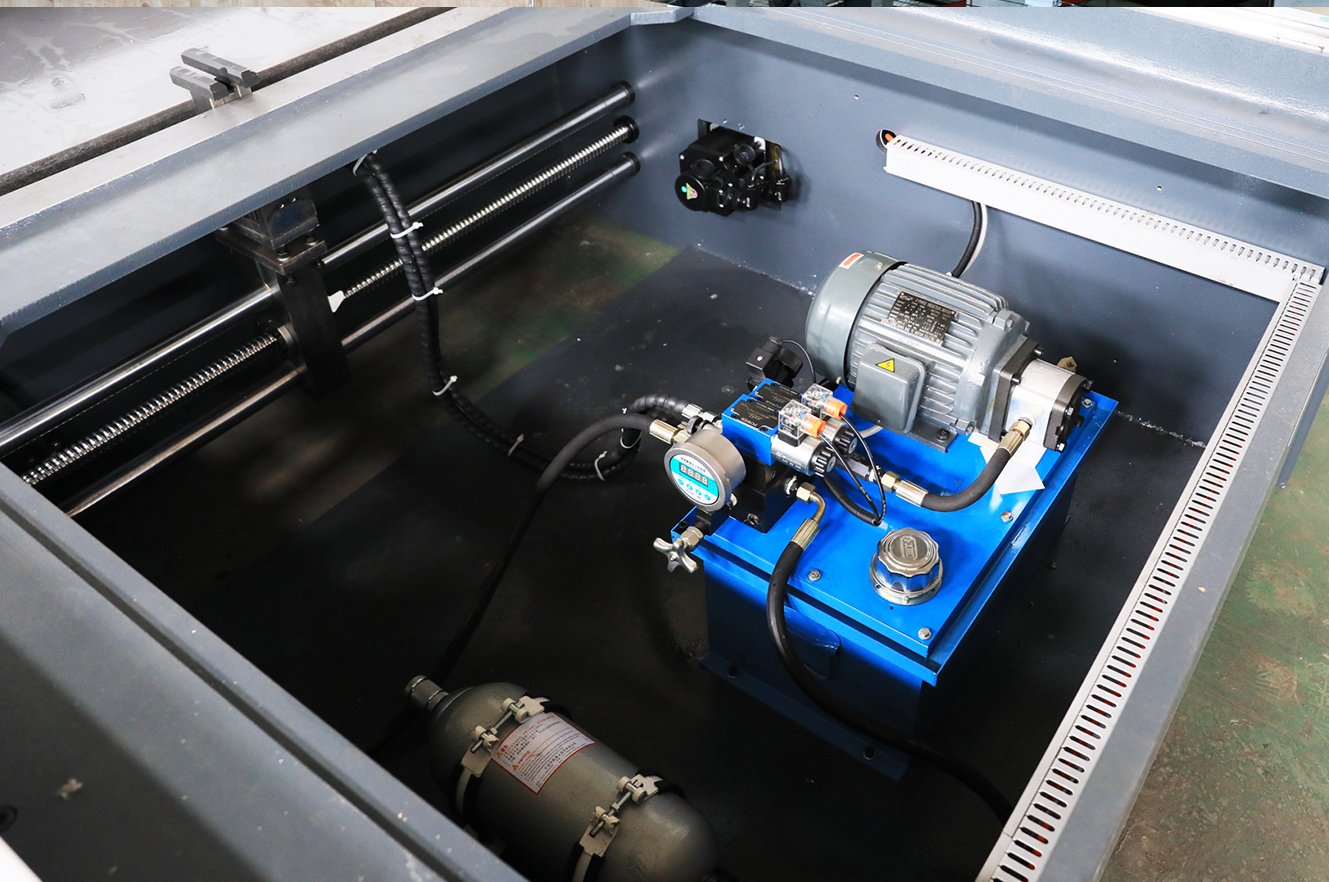

Hydraulic system

- The high-performance hydraulic system provides stable power output to ensure the smoothness and accuracy of slotting operations.

- The system is optimized to effectively reduce vibration and noise during operation, and supports high loads and long-term continuous work.

- The reliability of the hydraulic system not only ensures the safety of equipment operation, but also greatly reduces the maintenance frequency.

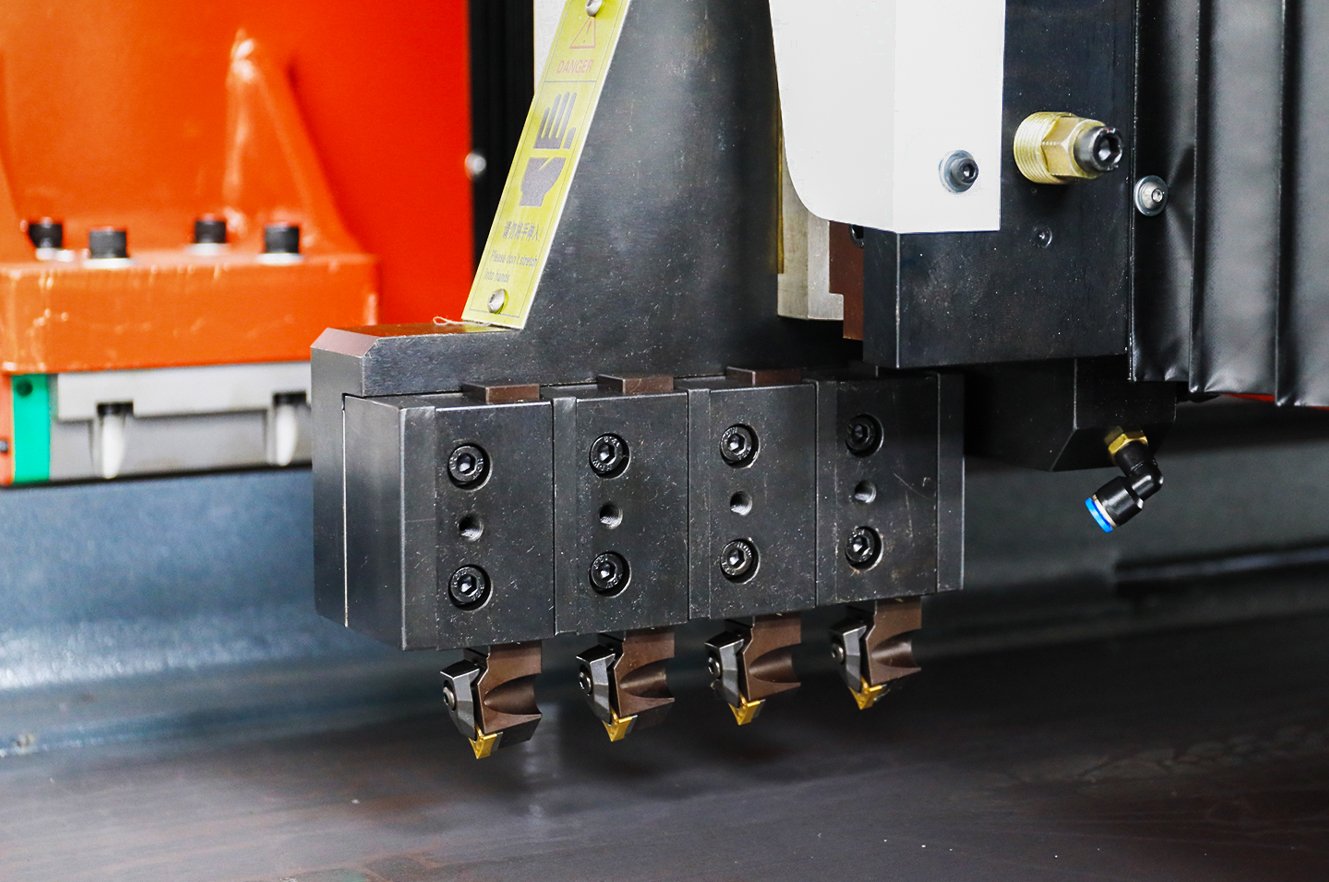

Alloy blade

- Use high-quality alloy blades with strong wear resistance, which are sharp and durable, and can easily cope with materials of different hardness.

- The excellent cutting performance of this blade reduces the frequency of thermal deformation and tool wear during processing, improves processing efficiency, and reduces replacement costs, bringing users a long-term use experience.

Product parameters:

| S.No. | product name | specifications and models | specifications and models | specifications and models | unit |

|---|---|---|---|---|---|

| 1250/3200 | 1600/3200 | 1600/4200 | |||

| 1 | Grinding length | 3200 | 3200 | 4200 | mm |

| 2 | Grinding width | 9-1250 | 9-1600 | 9-1600 | mm |

| 3 | Grinding thickness | 0.3-6 | 0.3-6 | 0.4-6 | mm |

| 4 | Fixed pressing plate | 12 | 12 | 16 | piece |

| 5 | Adjustable cramp | 11 | 11 | 15 | piece |

| 6 | Maximum X-axis itinerary | 3200 | 3200 | 4200 | mm |

| 7 | The X-axis servo-motor power | 4.5 | 4.5 | 4.5 | KW |

| 8 | The X-axis maximum movement speed | 100 | 100 | 100 | m/min |

| 9 | Z-axis maximum stroke | 10 | 10 | 10 | mm |

| 10 | Z-axis servo-motor power | 0.4/0.4 | 0.4/0.4 | 0.4/0.4 | KW |

| 11 | Z-axis maximum movement speed | 0.5 | 0.5 | 0.5 | m/min |

| 12 | The Y-axis servo-motor power | 2 | 2 | 2 | KW |

| 13 | Maximum movement speed of the Y-axis | 20 | 20 | 20 | m/min |

| 14 | Oil pump motor power (380 V-50Hz) | 2.2 | 2.2 | 2.2 | KW |

| 15 | fuel tankage | 35 | 35 | 35 | L |

| 16 | Overall dimension of the machine | 4800×2500×2150 | 4800×2800×2150 | 5800×2800×2200 | mm |

| 17 | bench height | 750 | 750 | 800 | mm |

| 18 | machine weight | About 8 | About 8 | About 10 | ton |