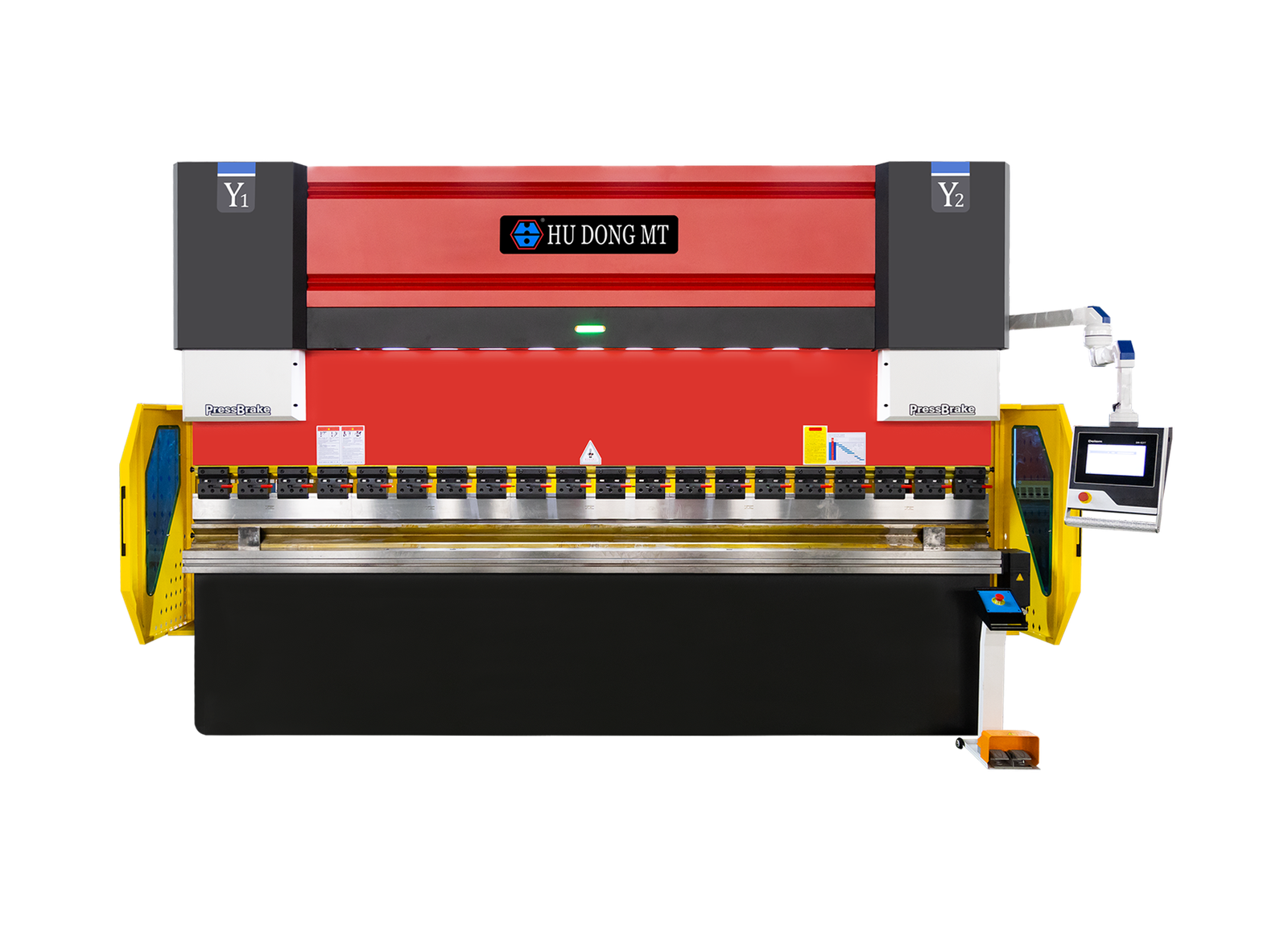

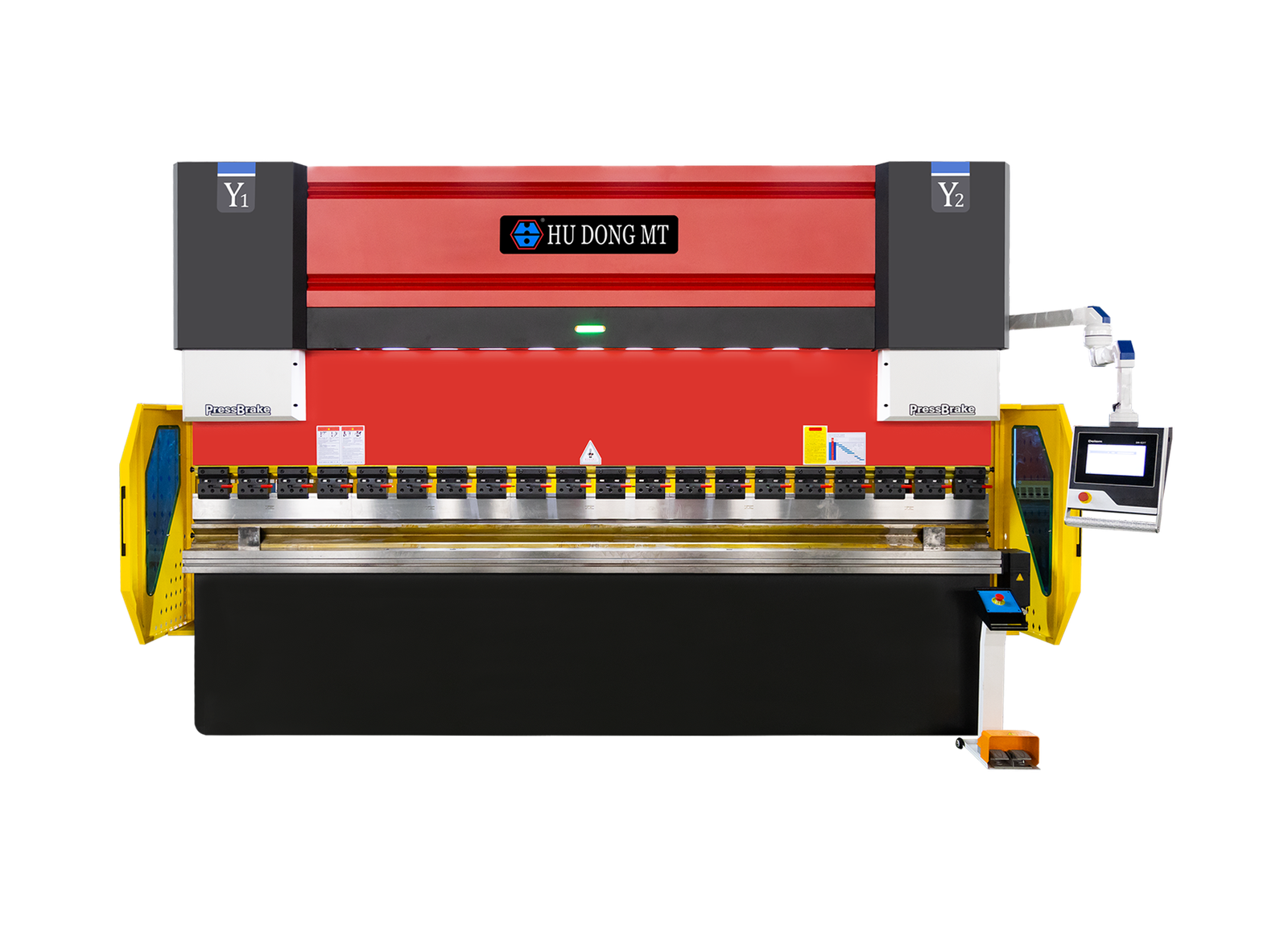

CNC Press Brake

Our electro-hydraulic CNC bending machines are equipped with top-quality components designed to achieve precise, durable and reliable processing. Our bending machines can provide efficient, reliable and high-quality processing results, making them a reliable choice for precision bending needs.

WF67K Series Technical Parameters

| type | Nominal force | Worktable length | Poles distance | Throat depth | Stroke | Max open | Power | Dimension |

| (KN) | (mm) | (mm) | (mm) | (mm) | (mm) | (KW) | L×W×H (mm) | |

| 40T/1600 | 400 | 1600 | 1300 | 250 | 130 | 450 | 5.5 | 2100×1300×2250 |

| 40T/2500 | 400 | 2500 | 2100 | 250 | 130 | 450 | 5.5 | 3000×1300×2250 |

| 70T/2500 | 700 | 2500 | 2100 | 320 | 130 | 450 | 7.5 | 3000×1350×2400 |

| 70T/3200 | 700 | 3200 | 2700 | 320 | 130 | 450 | 7.5 | 3700×1350×2400 |

| 90T/2500 | 900 | 2500 | 2100 | 320 | 130 | 450 | 7.5 | 3000×1350×2400 |

| 90T/3200 | 900 | 3200 | 2700 | 320 | 130 | 450 | 7.5 | 3700×1350×2400 |

| 110T/2500 | 1100 | 2500 | 2100 | 350 | 150 | 470 | 7.5 | 3000×1560×2455 |

| 110T/3200 | 1100 | 3200 | 2700 | 350 | 150 | 470 | 7.5 | 3700×1560×2455 |

| 110T/4000 | 1100 | 4000 | 3400 | 350 | 150 | 470 | 7.5 | 4500×1560×2455 |

| 130T/2500 | 1300 | 2500 | 2100 | 350 | 150 | 470 | 9 | 3000×1560×2455 |

| 130T/3200 | 1300 | 3200 | 2700 | 350 | 150 | 470 | 9 | 3700×1560×2455 |

| 130T/4000 | 1300 | 4000 | 3400 | 350 | 150 | 470 | 9 | 4500×1560×2455 |

| 170T/2500 | 1700 | 2500 | 2100 | 400 | 165 | 470 | 11 | 3000×1580×2500 |

| 170T/3200 | 1700 | 3200 | 2700 | 400 | 165 | 470 | 11 | 3700×1580×2550 |

| 170T/4000 | 1700 | 4000 | 3400 | 400 | 165 | 470 | 11 | 4500×1580×2550 |

| 170T/6000 | 1700 | 6000 | 5000 | 400 | 165 | 470 | 11 | 6500×1780×2970 |

| 220T/2500 | 2200 | 2500 | 2100 | 400 | 165 | 470 | 15 | 3000×1580×2500 |

| 220T/3200 | 2200 | 3200 | 2700 | 400 | 165 | 470 | 15 | 3700×1580×2550 |

| 220T/4000 | 2200 | 4000 | 3400 | 400 | 165 | 470 | 15 | 4500×1580×2550 |

| 220T/6000 | 2200 | 6000 | 5000 | 400 | 165 | 470 | 15 | 6500×1780×2970 |

| 260T/3200 | 2600 | 3200 | 2600 | 400 | 180 | 490 | 18.5 | 3700×1780×2750 |

| 260T/4000 | 2600 | 4000 | 3200 | 400 | 180 | 490 | 18.5 | 4500×1780×2750 |

| 260T/6000 | 2600 | 6000 | 5000 | 400 | 180 | 490 | 18.5 | 6500×1850×3600 |

| 300T/3200 | 3000 | 3200 | 2600 | 420 | 230 | 585 | 22 | 3700×2000×3200 |

| 300T/4000 | 3000 | 4000 | 3200 | 420 | 230 | 585 | 22 | 3700×1950×3100 |

| 300T/6000 | 3000 | 6000 | 4800 | 420 | 230 | 585 | 22 | 6500×2050×3700 |

| 400T/3200 | 4000 | 3200 | 2500 | 420 | 230 | 585 | 30 | 3700×2000×3300 |

| 400T/4000 | 4000 | 4000 | 3200 | 420 | 230 | 585 | 30 | 4500×2000×3300 |

| 400T/6000 | 4000 | 6000 | 4800 | 500 | 300 | 585 | 30 | 6500×2225×4000 |

| 500T/3200 | 5000 | 3200 | 2500 | 500 | 300 | 620 | 37 | 3700×2510×3750 |

| 500T/4000 | 5000 | 4000 | 3200 | 500 | 300 | 620 | 37 | 4500×2510×4260 |

| 500T/6000 | 5000 | 6000 | 5000 | 500 | 300 | 710 | 37 | 6500×2690×4475 |

| 600T/4000 | 6000 | 4000 | 3000 | 500 | 300 | 620 | 45 | 4500×2510×4260 |

| 600T/6000 | 6000 | 6000 | 5000 | 500 | 300 | 710 | 45 | 6500×2690×4475 |

| 800T/6000 | 8000 | 6000 | 5000 | 600 | 400 | 820 | 55 | 6500×2650×5500 |

| 800T/7000 | 8000 | 7000 | 5600 | 600 | 400 | 820 | 55 | 7500×2650×5700 |

| 800T/8000 | 8000 | 8000 | 6600 | 600 | 400 | 820 | 55 | 8500×2690×5900 |

| 1000T/6000 | 10000 | 6000 | 5000 | 600 | 400 | 1000 | 75 | 6500×3050×5700 |

| 1000T/7000 | 10000 | 7000 | 5600 | 600 | 400 | 1000 | 75 | 7500×3150×6000 |

| 1000T/8000 | 10000 | 8000 | 6600 | 600 | 400 | 1000 | 75 | 8500×3150×6500 |

Products Categories

Get A Free Quote

Get Free Quote of CNC Press Brake

Watch the video to learn about the product.

CNC System

- The controller is the core of the whole machine. Our company provides controllers of internationally renowned brands such as Delem of the Netherlands, ESA of Italy, and Cybelec of Switzerland. They support 2D and 3D graphic editing functions, making programming simpler and more accurate.

- The excellent performance of this series of controllers has been widely recognized by the industry. Compared with general controllers, it has advantages in reliability, accuracy, and ease of operation. It can easily cope with complex processes and improve production efficiency. It is an ideal choice for precision sheet metal processing.

Bending Mold

- The mold is made of 42CrMo mold steel with an overall hardness of 47 degrees, excellent quality and durability. The upper mold is installed on the slide and fixed with a precision quick clamping device;

- The use of single V and double V molds can make mold replacement convenient and fast, reduce labor intensity and improve production efficiency.

- The mold supports customized standard molds or non-standard molds.

Crowning

- Very precise bending angles, Euro-style dies, 60 mm and 90 mm.

- Base can be clamped together with a single die with 13 mm tang, electric crowning with controller.

- Precise positioning and alignment of the crowning table, easy and quick to use.

Main Motor

- Our bending machines use main motors from world-renowned brands such as Siemens, Bosch Rexroth, and Inovance.

- This series of motors is known for its high stability, strong torque output, excellent energy efficiency ratio and precise control. It is not only suitable for long-term load operation, but also ensures the continuous reliability of the equipment under high-precision requirements, helping us provide customers with high-quality and efficient bending solutions.

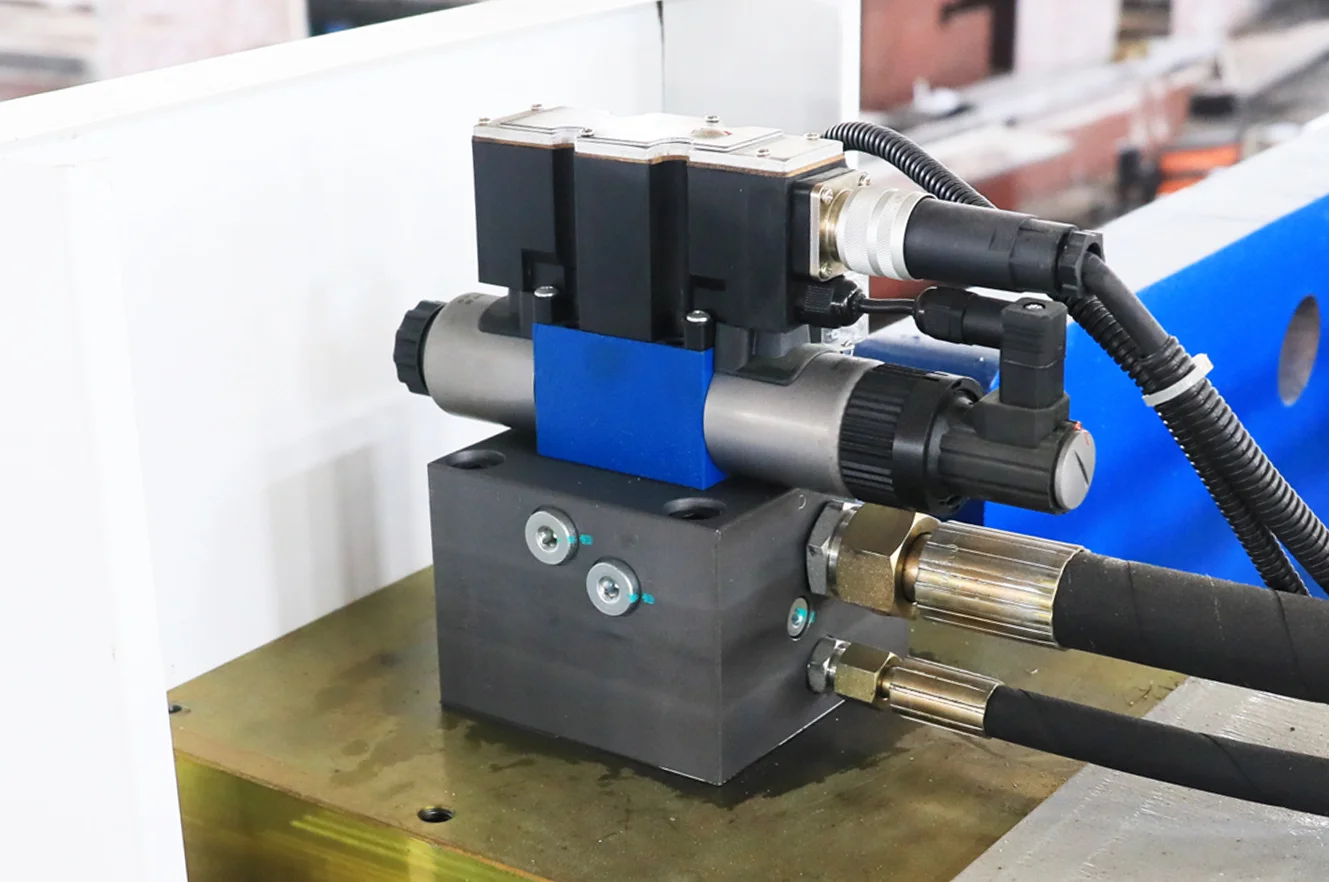

Hydraulic System

- Our hydraulic control system adopts electro-hydraulic servo synchronous design. The hydraulic cylinder spacing is extremely small, the anti-eccentric load capacity is strong, the synchronization accuracy is high, the power density ratio is excellent, and the cost is low. The hydraulic system pressure can be adjusted according to actual needs to meet different bending force requirements.

- For the accessories of the hydraulic system, we chose famous brands such as German hawe and Rexroth, with high efficiency and low failure rate to ensure the reliability of the equipment and the continuity of production.

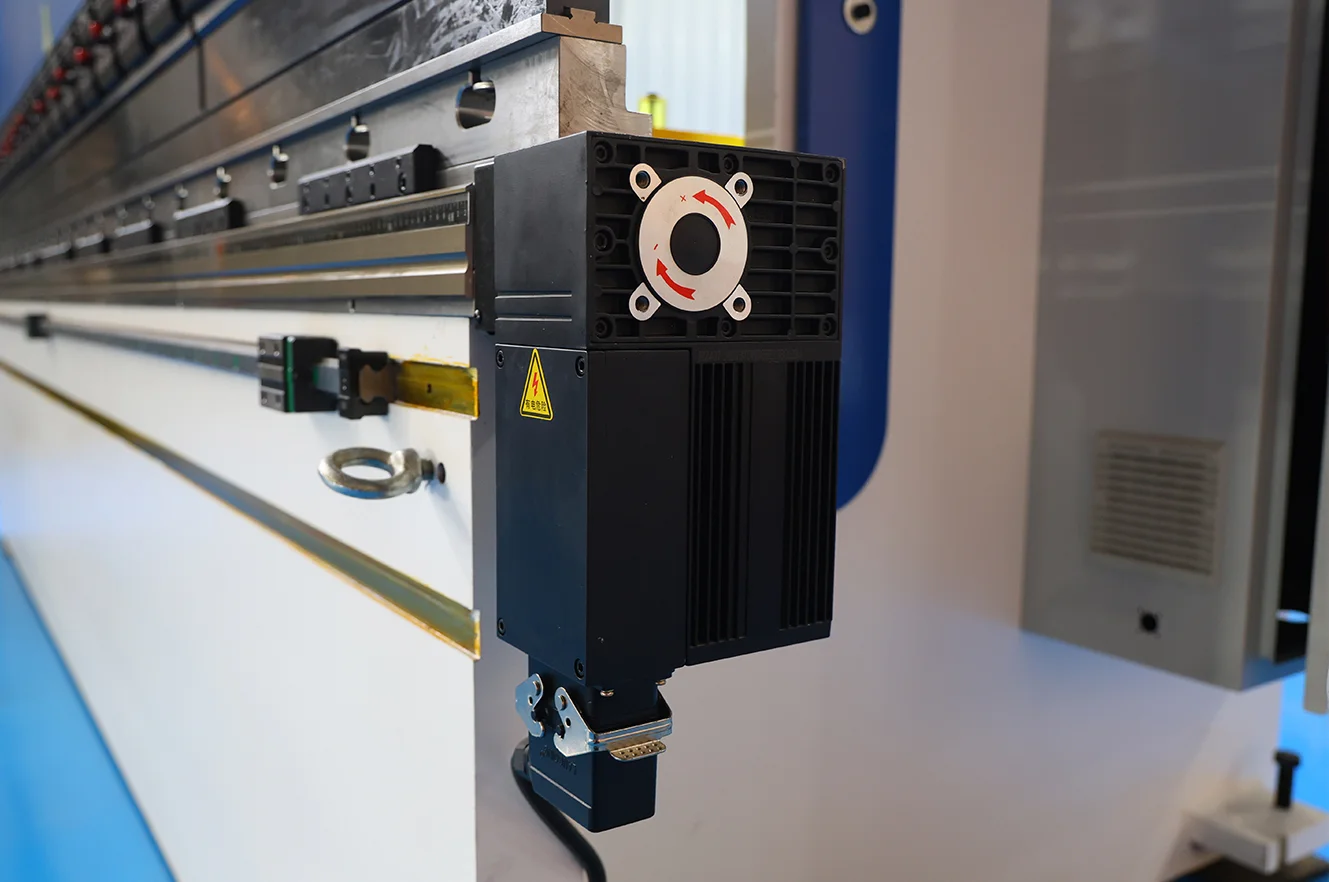

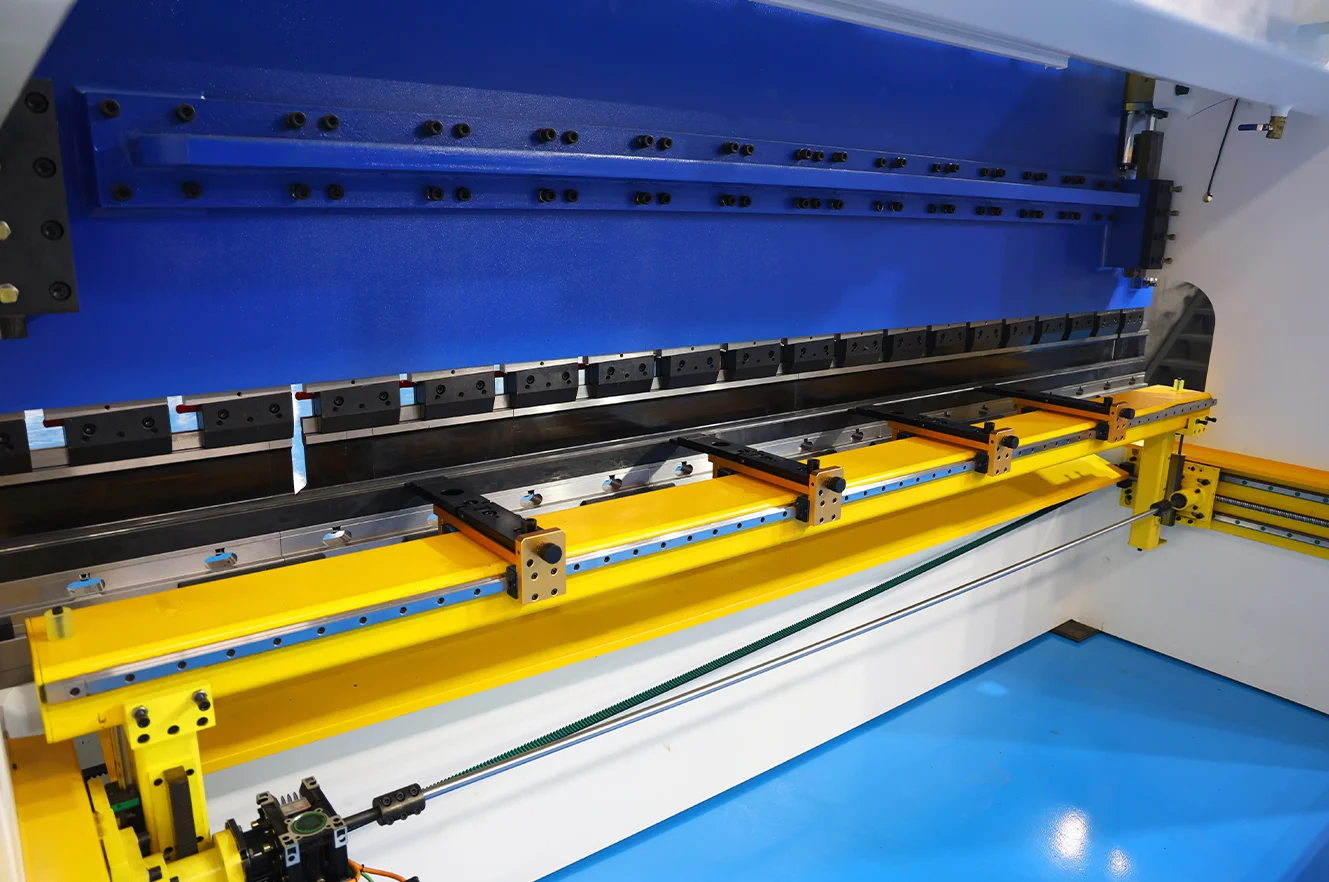

Back Gauge Device

- The entire back gauge system is subjected to high temperature tempering treatment to eliminate internal stress, enhance the plasticity and toughness of the metal, and avoid loss of precision due to frame deformation

- In order to ensure the motion accuracy of the X-axis, we use imported ball screws and linear guides to replace the traditional screw design, which greatly improves the accuracy and consistency of the processing process.

- The back gauge uses a synchronous pulley mechanism driven by a servo motor to replace the stepper motor, ensuring better control performance and processing accuracy.

Fast Clamp

- safe and fast tool change

- substantial improvement in timeconsumption and related costs

- Secure against tool falling down

- Available in manual, pneumaticand hydraulic models

- Mounting: Simply from the bottominto the housing, tighten-DONE

Electrical Components

- Our equipment uses high-quality electrical parts that perform reliably even with unstable power supply, and replacement parts are easily available worldwide.

- We use genuine Schneider components imported from France, known for their stability, durability, and long service life.

Related Products

Related News

[product_related_posts]